Do you know the operation process and classification of JP Outdoor Integrated Distribution Box?

JP Outdoor Integrated Distribution Box operation

process:

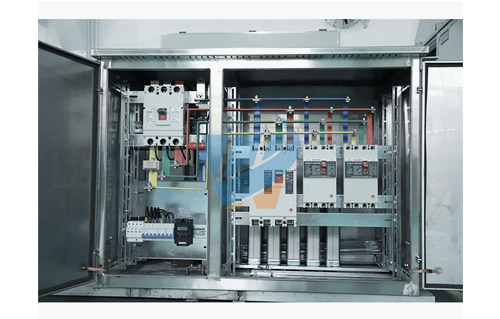

Requirements for secondary wiring construction: construction according to the drawing, the wiring is correct; the wires and electrical components are bolted, plugged, welded or crimped, etc., should be firm and reliable, and the wiring is good; the wiring is neat, clean, and beautiful; the wires are well insulated, No damage; there should be no connectors in the wires in the cabinet; the circuit number is correct, and the handwriting is clear.

JP Outdoor Integrated Distribution Box

The selection of cable core section should also meet the following requirements:

(1) Current loop: The accuracy level of the current transformer should be made. At this time, if there is no reliable basis, the maximum short-circuit current can be determined according to the current capacity of the circuit breaker.

(2) Voltage loop: When all protection devices and safety automatic devices are operated (taking into account the development, the load of the voltage transformer is the largest), the voltage drop from the voltage transformer to the protection and automatic device screen should not exceed 3 of the rated voltage.

(3) Operating circuit: Under the maximum load, the voltage drop from operating the bus to the equipment should not exceed 10% of the rated voltage.

3. The secondary winding of the current transformer is not allowed to open. No short circuit allowed on the secondary side of the voltage transformer

Before secondary wiring, you should be familiar with the drawings:

1.Schematic diagram

2.Expanded view

3.Terminal block diagram

4. installation wiring diagram

Distribution boxes are classified by structural characteristics and use.

The functional unit and the bus or cable are separated by a grounded metal plate or a functional board made of plastic to form three areas of the bus, functional unit and cable. There are also isolation measures between each functional unit. Drawer switchgear has higher reliability, safety and interchangeability. It is more advanced switchgear. Most switchgear refers to drawer type switchgear. They are suitable for industrial and mining enterprises and high-rise buildings that require high reliability of power supply, as a centralized control power distribution center. Power and lighting distribution control box. Most are enclosed vertical installations. Due to different application occasions, the enclosure protection levels are also different. They are mainly used as power distribution devices on the production site of industrial and mining enterprises.

As a China High Voltage Switch Cabinet Factory, share with you the differences between power distribution cabinets and distribution boxes:

1. In terms of use, distribution boxes are generally used by households, while distribution cabinets are mostly used in centralized power supply, such as industrial electricity and building electricity. Distribution boxes and distribution cabinets are complete sets of equipment. The distribution box is a low-voltage complete set of equipment, and the distribution cabinet has high voltage and low voltage.

2. The most basic difference in appearance and size is the size. The power distribution cabinet is placed on the ground and is as large as a refrigerator. The distribution box is small in size as a box is fixed on the wall, and the two functions the same.

3. The distribution box is generally a terminal product applicable standard GB7251.3 can be operated by non-professionals, the maximum current is 250A. Power distribution cabinets are generally different standards for controlling and distributing electrical energy.

4. Formally, the distribution cabinet is a vertical cabinet as its name, and the distribution box is a box type.

5. Functionally, the distribution cabinet can be equipped with various explosion-proof electrical appliances or various explosion-proof electrical appliances, such as explosion-proof power (lighting) distribution boxes, explosion-proof electromagnetic starters, explosion-proof power maintenance boxes, etc. Components such as contactors, contactors, thermal relays, buttons and indicators can be used for lighting and power motor control. We have Outdoor Vacuum Short Circuit on sale, welcome to consult.