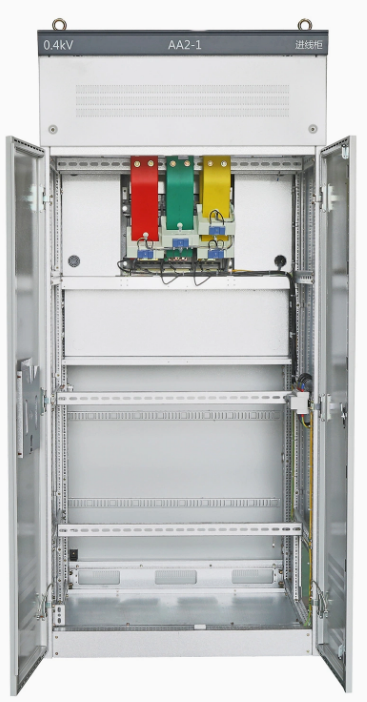

I. Overview

PLC control cabinet is an electric cabinet with PLC as the core control unit, which can realize the control of fans, pumps, electric valves and other field equipment. According to the actual control scale, the automatic control of single cabinet can be realized, and the DCS control system can also be composed of multi cabinets through industrial Ethernet or industrial fieldbus network. It is widely used in electric power, metallurgy, chemical industry, papermaking, environmental protection sewage treatment and other operations. It can realize remote assistant control, data acquisition, real-time data transmission, online data analysis, large data analysis and application, etc.

Ⅱ. Systematic Programmes and Characteristics

1. PLC + Relay Control System

Suitable for small-scale control system. The relay hardware circuit is mainly used to control the system, and the simple automation control is mainly realized. Principle: In manual mode, the user can control the field equipment manually according to the button instructions on the operation panel of the control door; in automatic mode, the small PLC can output the contact signal of the intermediate relay through the logical operation of the program according to the received control conditions, and drive the control unit of the equipment (such as the controlled motor) with this signal. AC contactor, electric control valve, solenoid valve, frequency converter, soft starter, etc., to achieve the purpose of control.

Advantages: Easy operation, low technical requirements for operators. The system runs safely and reliably, maintains conveniently and costs low.

2. PLC + Touch Screen Control System

The application of touch screen greatly improves the automation of the system. By using the control of touch screen and PLC, not only the system parameters can be read and written at any time, but also the function of multi-control mode selection can be realized according to its formula function. In addition, because the touch screen has its own storage space, it can record the historical alarm and use process of the system for operators and maintenance personnel to view and analyze. Touch screen pair, analog data recording is also more convenient value view. The bar chart and curve provided by the touch screen are very convenient to record and realize real-time or historical measurement data for users to analyze the operation of the system or control the process reality.

Advantages: Soft components inside the touch screen can directly send out the intermediate registers inside the PLC, greatly reducing the control buttons and indicator lights on the control cabinet operation panel.

3. PLC + PC Control System

The central control room is equipped with industrial computers with high computing speed and large storage capacity. By connecting field bus with PLC, the data of real-time working condition, process variables, process indexes and process parameters collected by field PLC are displayed to users in the form of graphics, reports and curves, which provide a convenient man-machine interface and centralized management function. Various dispatching instructions and processes are issued by mouse or keyboard. Parameter setting. Users need not worry about the expansion of follow-up equipment. If they add control equipment (such as PLC cabinet), they only need to connect the new equipment to the communication network and load the control program in the configuration software of the host computer.

Advantages: Stronger communication capability. Industrial configuration software basically covers all communication modes. In addition, the realistic simulation ability is also the characteristic of industrial configuration software. Users only need to observe the running state of field equipment in the central control room, and can operate remotely.

III. Parameter Information

| Standard type | Customized | |

| Core Frequency Converter Components | SIEMENS Frequency converter | SIEMENS Inverter or customer provided |

| Optional power | 1.1kW~560kW | |

| Low Voltage Components and Display Instruments (Optional) | Type A: Low Voltage is Schneider Circuit Breaker and Contactor,Display Instrument is Multifunctional Meter (Including Power and Electricity) | Type B: Low-voltage circuit breaker and contactor, display instrument is pointer meter. |

| Number of control motors | l One control unit can be selected. Up to one motor to control seven motorsl One of them controls one motor as a standard cabinet, and the other controls two or more motors, which need to be customized. | |

| Alarm instruction | Yes | Yes |

| 485 Interface | Yes | Yes |

| Local/remote control switching | Yes | Yes |